Yara needed a precise, cost-effective way to measure silo occupancy across facilities. Existing methods were unreliable, slow, and posed safety risks. The challenge required on-site experimentation in hazardous environments while ensuring compliance with strict safety protocols.

A prototype leveraging 3D modeling with Kinect sensors to scan silo contents safely and accurately. This solution outperformed manual measurement systems in precision, speed, and cost-efficiency while maintaining mobility and safety.

I led the design sprints, conducted user research, facilitated discovery workshops, and collaborated with a multidisciplinary team. I also tested and refined prototypes, ensuring alignment with user needs and operational constraints.

Starting with research and a discovery workshop, we defined project scope, success metrics, and logistics. Through iterative sprints using the Design Sprint methodology, we explored mechanical and digital solutions, from pulley-based systems to image-based 3D modeling. After testing multiple approaches, we refined a Kinect-based solution that delivered 98% accuracy, significantly improving efficiency and safety.

The 98% accuracy achived meant that the methods discovered by this proof of concept fulfilled the requirements. Given the initial costs of the existing solutions on the market being over $25,000, the costs of a kinect + a tablet would be below $500 in comparison, making it an extremely more affordable solution that would scale to as many silos as needed, unlike the existing solutions.

LOCATIONS: Porto Alegre (Brazil)

PROCESS, TECHNOLOGIES AND TECHNIQUES:Research Service Design Design Sprints

Project description

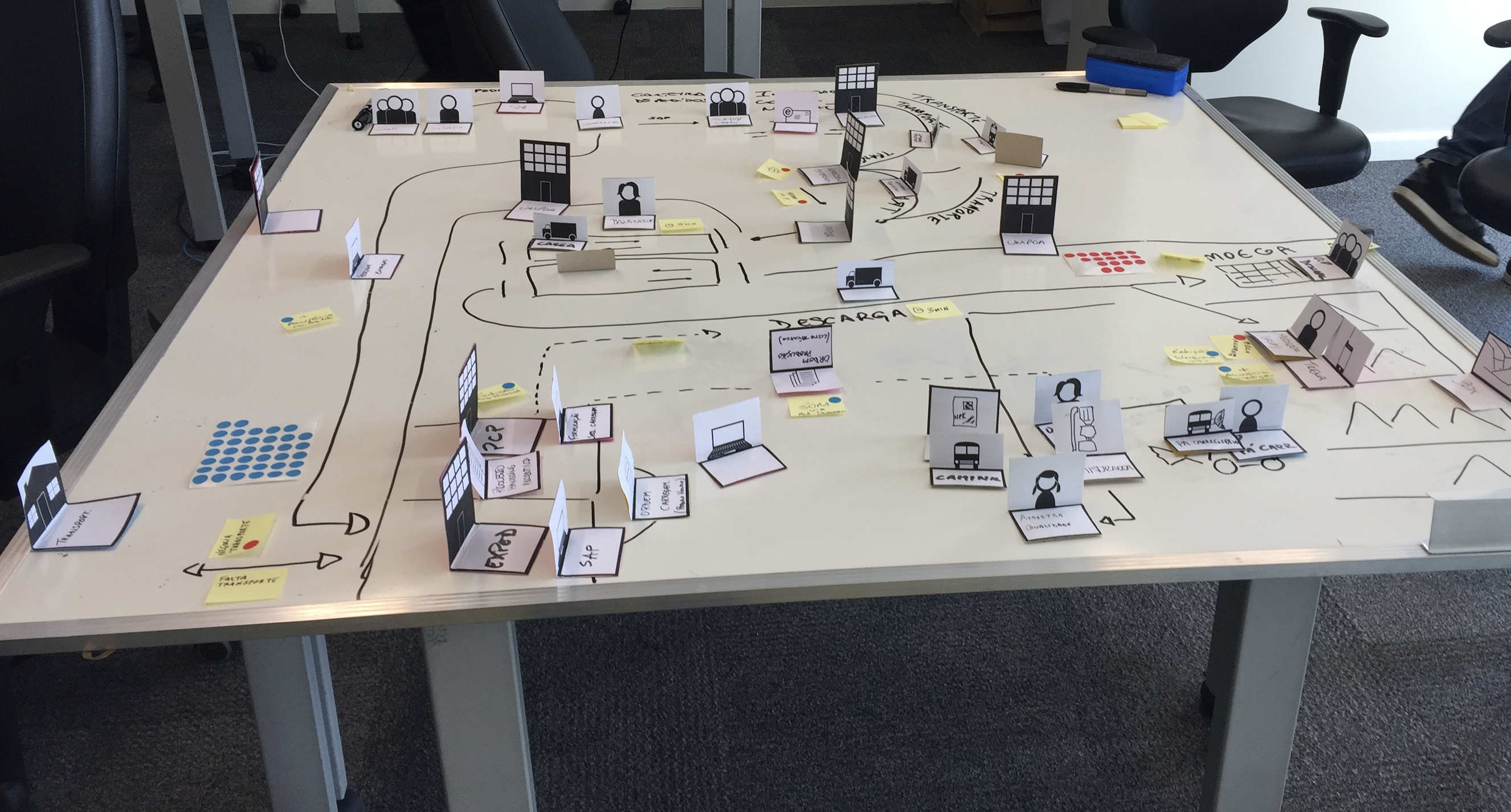

Yara approached us with a unique challenge: they needed a better way to measure silo occupancy levels across their facilities. We initiated an experimentation process based on Design Sprints, collaborating with a multidisciplinary team to hypothesize, prototype, and test solutions.

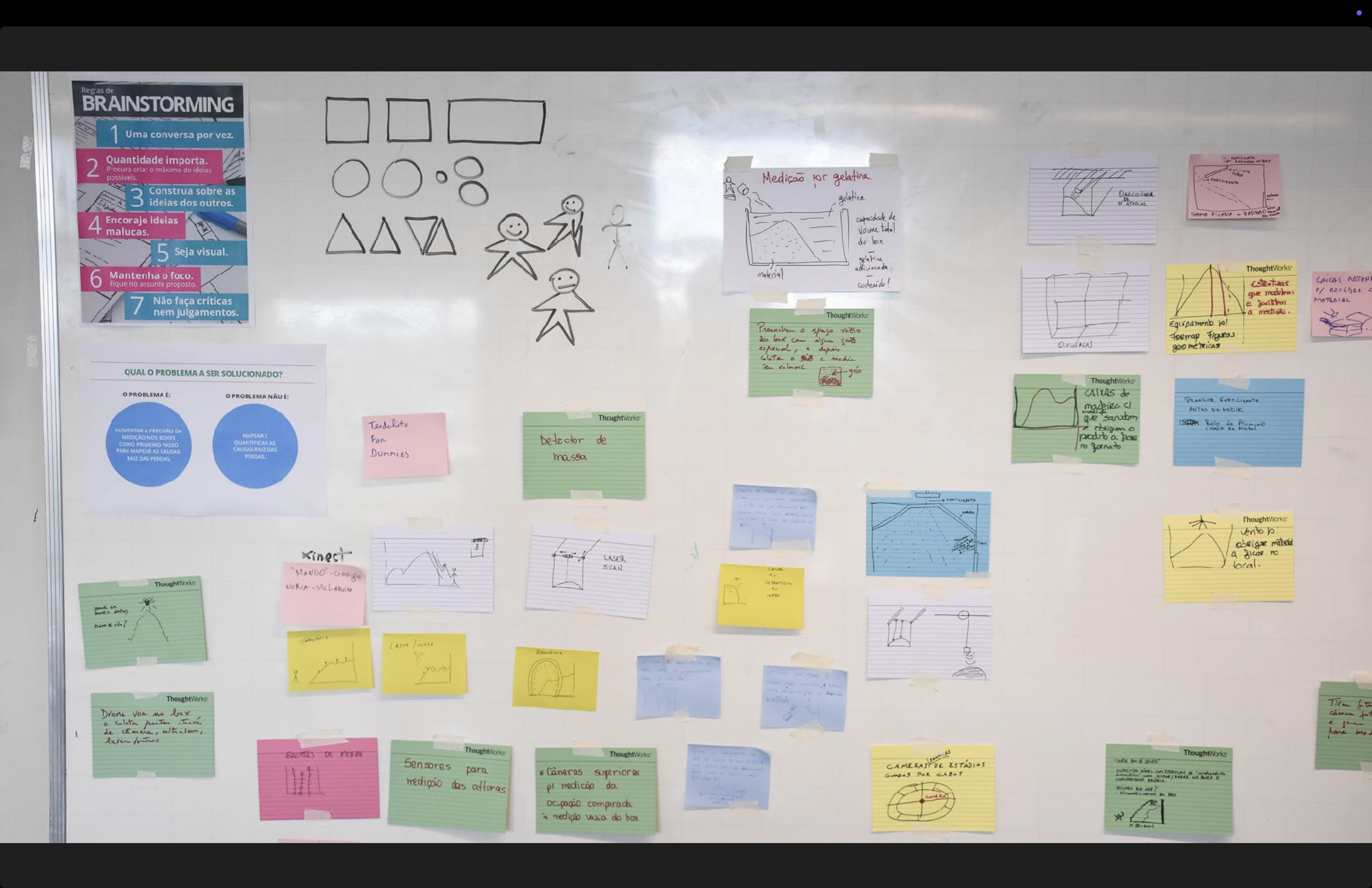

We have started with a few interviews and study before running a Discovery workshop focused on defining what would be the scope, approach, success metrics and logistcs, since a big part of the project took place on site - that is, inside the silos, surrounded by mountains of tons of grains and chemicals - with all proper safety equipment and following the client’s safety protocols.

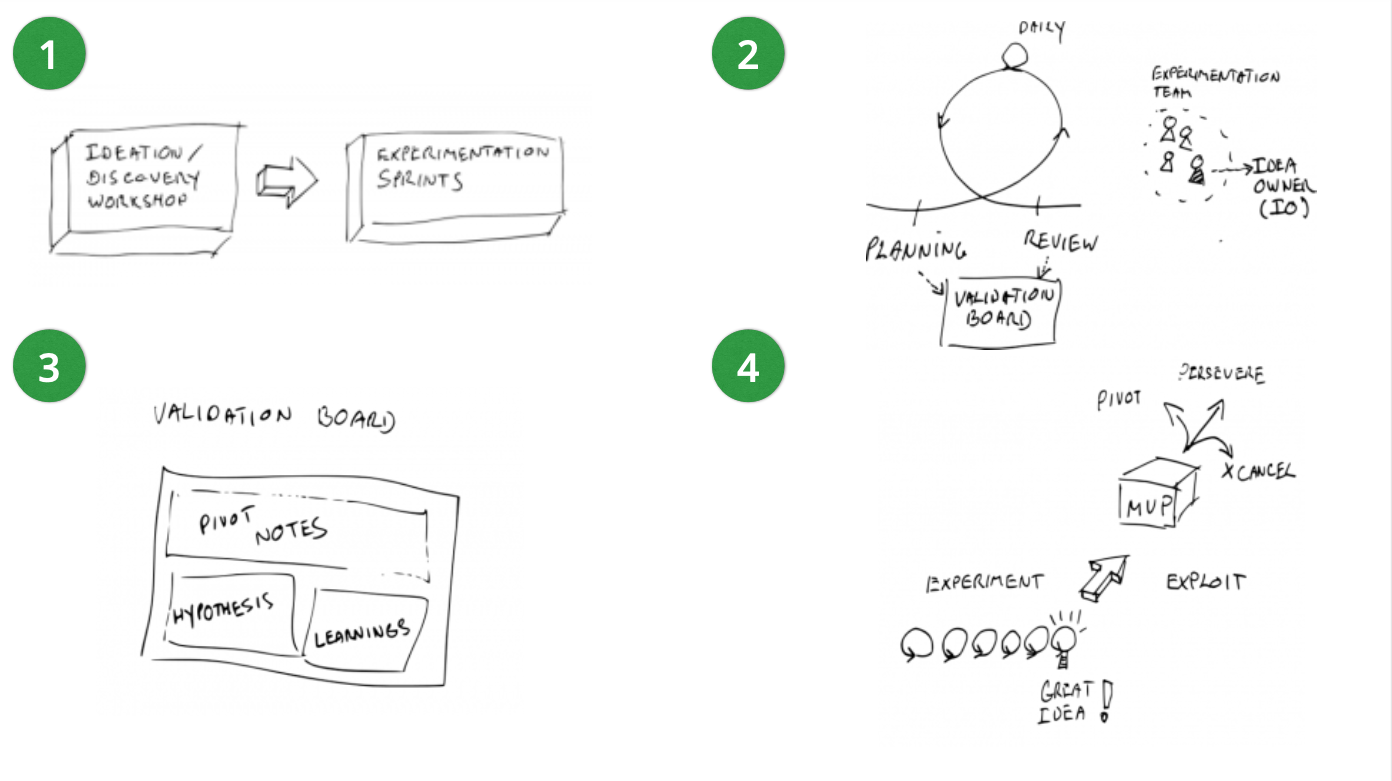

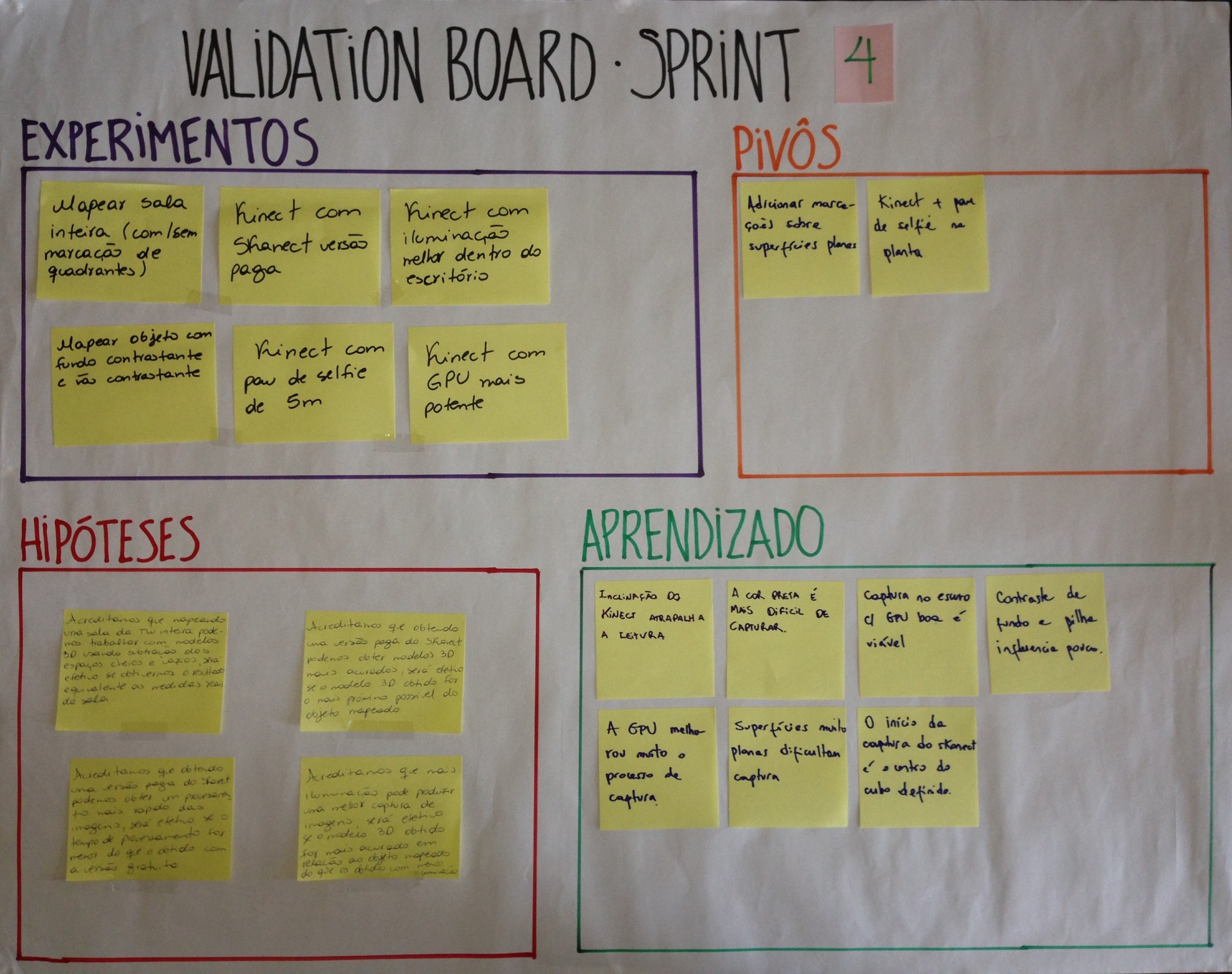

We have also defined the ways of working, which included weekly showcases and a validation board which described our hypothesis, the learnings and pivot notes.

We explored diverse methods, from manual measurements using pulley systems to advanced 3D modeling with Kinect sensors and mobile systems.

Design Sprints

Sprint 1

Having decided to move fast using the experimentation methodology of Design Sprints, we have have decided to start with the simpler way of learning

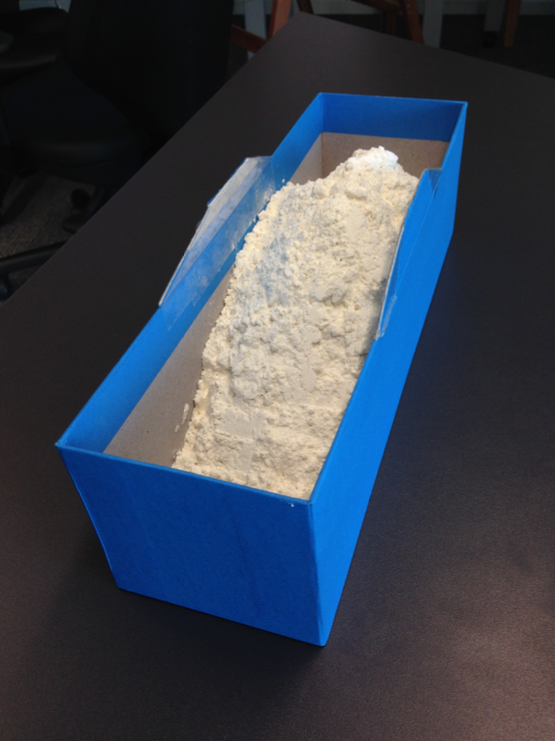

We started playing with more mechanical solutions, including fishing rods, windlasses and sinkers, among may other pulley systems. One of the first experients consisted of building a miniature version of a silo to experiment with and validate our results.

Sprint 2

Learning through the sprints that 3D modeling could grant us much more mobility, we dwelved into different ways of making such models - for example, capturing multiple images with a tablet to then feed them to a prototype system that would render it.

Sprint 3

Since gathering the images and working with them to build a 3D render was resulting in complex processing and less accurate results, we searched for other ways to capture such images. The best way we could find with an existing tool was to use the Microsoft Kinnect sensor plugged to a laptop, which proved to be a cheap and quite accurate solution.

Sprint 4

Having achieved great results with the Kinnect sensor and the laptop, a still remaining issue we had was mobility. We were able to employ a lightweight software solution that could be ran from a tablet, keeping the Kinnect sensor as the main source of 3D capture.

Results

By the end of the engagement, we developed a solution with over 97% measurement accuracy. This prototype not only exceeded the accuracy of their existing methods but also drastically reduced time and cost while enhancing employee safety. It was a rewarding project, merging creative problem-solving with practical implementation.

For following steps, we have identified some key improvements that could still be made, such as testing the mobility with drones, dedicated 3D scanners with longer reach, a custom 3D modelling software tailored to specific needs with measurement automations considering pile densities and more irregular, spread out piles in one silo.